Published : 2026-01-05

The world's longest expressway tunnel, Xinjiang's Tianshan Shengli Tunnel, recently opened to traffic. It tunnelled through the Tianshan Mountains and connects northern and southern Xinjiang. This tunnel has significantly reduced the original 3-hour journey on winding mountain roads to just 20 minutes.

Why was it necessary to take on the hell-level engineering challenge in the Tianshan Mountains? How did China’s infrastructure holic once again turn impassable terrain into accessible routes?

Why was it necessary to tunnel through Tianshan Mountains?

This 22.13-kilometre tunnel is equivalent to the total length of 10 Hong Kong's Tsing Ma Bridge. The Tianshan Shengli Tunnel is part of the Urumqi-Yuli Expressway, and its opening to traffic also signifies that the entire Urumqi-Yuli Expressway entered operation.

After opening to traffic, the travel time from Xinjiang Urumqi to Korla has been shortened from 7 hours to 3.5 hours.

This means that the history of travelling across Tianshan between northern and southern Xinjiang has been rewritten, and the geographical barrier is completely overcome. The flow of people and goods between northern and southern Xinjiang has become faster, and economic ties have grown closer.

The opening of the Tianshan Shengli Tunnel is far more than a world record. It brings many benefits to the people. Firstly, during the construction and operational periods, the project provided 1,582 and 1,210 jobs respectively for local people, of which over 80% were for ethnic minorities.

Secondly, the shortened travel time across the north and south of Tianshan Mountains makes one-day trip between northern and southern Xinjiang a reality, also enabling tourists to explore Xinjiang more efficiently. New tourism models and products will be developed, bringing new opportunities for the tourism industry along the route.

Tackling hell-level engineering difficulty

The geology of Tianshan Mountains is extremely complex. The construction team must contend with as many as 16 fault zones and various adverse geological conditions. Some of the rock would crumble in hand after being exposed to surging groundwater. An engineer described: "Building a tunnel in the Tianshan Mountains is like doing engineering work in soft tofu."

Faced with such a hell-level challenge, the engineers used the world's first New Grouting Method Hard Rock Tunnel Boring Machine (TBM), which was independently developed in China.

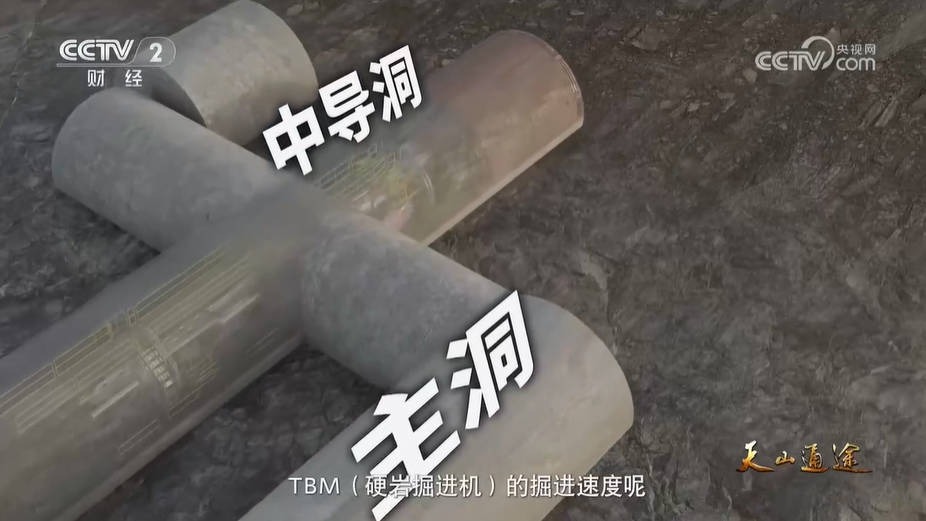

At the same time, the project also implemented China's first 'three-tunnel parallel construction' plan, which increased the number of workfaces. At its peak, 14 workfaces operating simultaneously, which reduced the difficulty of excavating a single tunnel and successfully shortened the tunnel construction period from 10 years to just 5 years.

In addition, the maximum ground stress in the tunnel reaches nearly 22 megapascals, which is equivalent to a fingernail-size rock bearing a weight of over 200 kilograms. To resist the intense pressure, the construction team developed 70-centimetre-thick foamed concrete as a shock-absorbing and energy-dissipating structure.

For such a difficult project, the construction process was certainly not smooth.

During the excavation process, a fault alteration zone not discovered by early geological surveys almost became an obstacle. The TBM's cutterhead is designed for hard rock, not soft mud, so it got stuck in the paste-like mud. The TBM was like an elephant sinking into a swamp. It took the team 14 months to advance just over 30 metres and finally rescue the trapped TBM.

How does an ultra-long tunnel breathe and stay warm?

However, even after boring through the ultra-long tunnel, two other challenges needed to be considered—ventilation and insulation.

The Tianshan Shengli Tunnel has a maximum burial depth of over 1,100 metres. Can such a deep and long tunnel rely only on ventilation from the exits at both ends?

The answer is no. Ventilation inside the tunnel requires the use of vertical shafts. Engineers devised a way for four sets of ventilation shafts to descend from the mountaintop, connecting the two main tunnels and splitting the tunnel into five sections for separate ventilation.

Therefore, in addition to being the "world's longest motorway tunnel", the tunnel also holds another world record—the world's deepest, largest-diameter, and highest-altitude expressway vertical shaft. It reaches a depth of 707 metres, equivalent to the height of 2 Hong Kong's The Centre buildings.

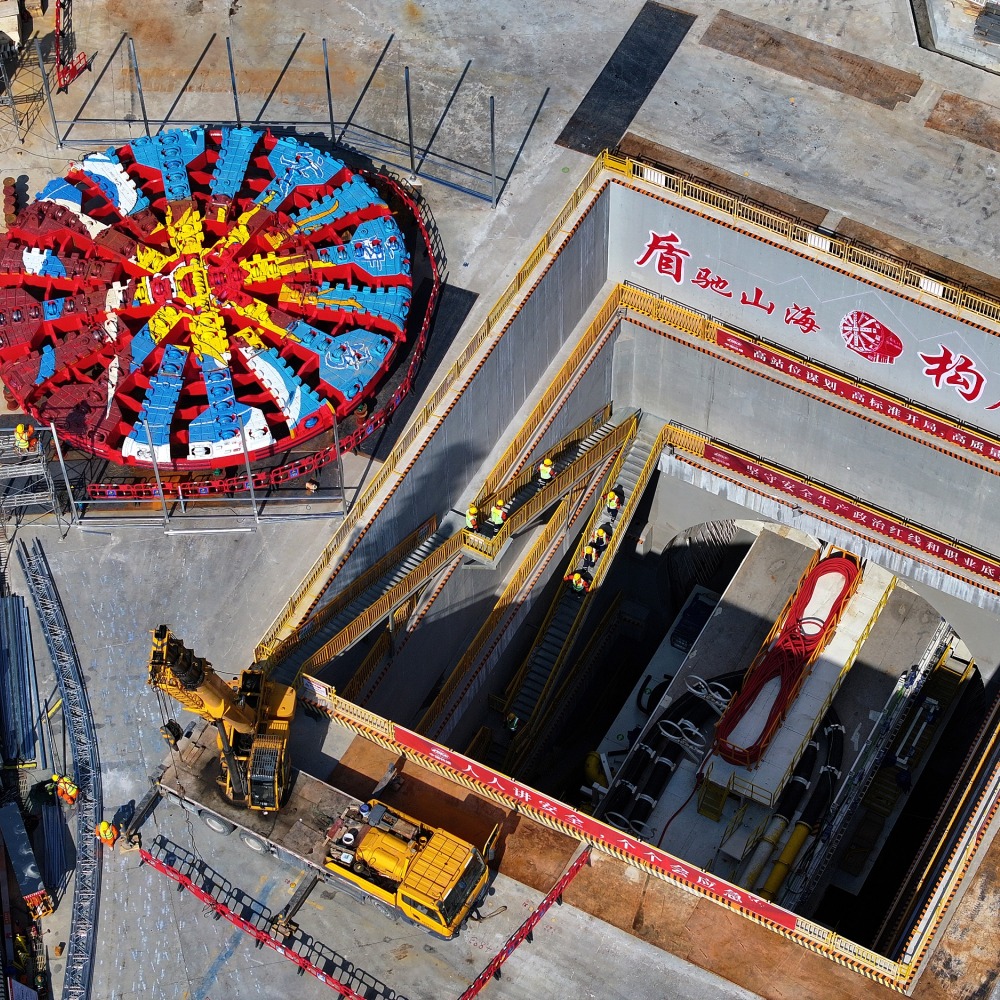

A vertical shaft of this scale cannot be excavated by an ordinary TBM. To overcome limitations from factors such as terrain, China independently developed the world's first high-altitude, cold-region, ultra-large-diameter hard rock vertical boring machine—the Shouchuang. The brand-new drilling process it employs both enables unmanned underground operations and avoids environmental pollution from slag discharge.

With the ventilation problem solved, how about insulation?

It is important to know that the Tianshan Shengli Tunnel is located in a high-altitude, cold environment of over 3,000 metres, with an average annual temperature of -5.4°C and a minimum temperature that can reach minus 41.5°C. If insulation measures are not taken, it is highly likely that ice formation will affect road surface conditions and even damage the tunnel structure.

In addition to laying an insulation layer on the concrete surface, the team also cleverly utilised the constant-temperature geothermal resources inside the mountain, drilling 80 metres deep (equivalent to a 30-storey building) to provide stable heating for the tunnel through heat exchange pipelines.

Building wastewater treatment plants to protect the Tianshan ecosystem

The construction of Tianshan Shengli Tunnel not only faced geological and engineering difficulties, but also challenges in ecological conservation.

Just over 10 kilometres from the entrance portal of the Tianshan Shengli Tunnel is the Tianshan Glacier No. 1 conservation area, a habitat for snow leopards. The entire construction route passes through the Urumqi River's Level II drinking water source protection area, and no pollution could be caused.

To properly handle the massive amount of water discharged from within the tunnel, a total of three wastewater treatment plants were built inside and outside the tunnel.

The plants treated the construction wastewater generated during the tunnel excavation process and the fissure water gushing from the Tianshan fault zone, with all of it being recycled for use in tunnel production, equipment cooling, road dust suppression, vegetation greening, and so on.

The Urumqi-Yuli Expressway, which contains the Tianshan Shengli Tunnel, along with other major arteries now under construction like the Zhaosu-Wensu Expressway and the Duku Expressway, are together weaving a "seven horizontal and eight vertical" three-dimensional transport network.

Heading east for over 3,000 kilometres, you can reach any city in China, heading west for over 3,000 kilometres, you can also reach any country in Central Asia.

The goal of "forming a circular route within Xinjiang, speeding up entry to and exit from Xinjiang, creating smooth travel between northern and southern Xinjiang, and establishing connections for crossing borders" is being rapidly realised.